Overcoming Supply Chain Challenges in the Fresh Produce Industry

The fresh produce industry is a critical part of the global food supply chain, providing consumers with essential fruits, vegetables, and other perishable items. However, the supply chain for fresh produce is complex and fraught with challenges that can significantly impact product quality, shelf life, and availability. From farm to table, fresh produce must navigate a myriad of logistical hurdles, including transportation delays, storage issues, and regulatory compliance. These challenges are compounded by the perishable nature of the products, which require careful handling and swift delivery to ensure freshness.

This article explores the key supply chain challenges faced by the fresh produce industry and provides actionable strategies to overcome them. By optimizing the supply chain, stakeholders can improve efficiency, reduce waste, and ensure that high-quality produce reaches consumers in a timely manner.

The Complexity of the Fresh Produce Supply Chain

The fresh produce supply chain is a multifaceted network involving various stages, including production, harvesting, processing, packaging, transportation, storage, and distribution. Each stage presents its own set of challenges, which can vary depending on the type of produce, geographic location, and market demands.

Production and Harvesting: The journey of fresh produce begins on the farm, where crops are cultivated and harvested. Factors such as climate conditions, soil quality, and farming practices play a crucial role in determining the yield and quality of the produce. However, unpredictable weather patterns, pests, and diseases can disrupt the growing season, leading to reduced yields and quality issues. For example, the United Nations estimates that up to 40% of global crop yields are lost each year due to pests and diseases (FAO).

Processing and Packaging: After harvesting, fresh produce must be processed and packaged to ensure it is ready for transportation and retail. This stage involves washing, sorting, grading, and packaging the produce. Improper handling during this phase can lead to damage, contamination, and spoilage. According to the World Resources Institute, approximately 14% of the world’s food is lost between harvest and retail (WRI).

Transportation: Transportation is one of the most critical stages in the fresh produce supply chain. The perishable nature of the products requires them to be transported quickly and under controlled conditions, such as refrigeration, to prevent spoilage. Delays in transportation, inadequate temperature control, and rough handling can lead to significant losses. In fact, studies have shown that up to 50% of fruits and vegetables are lost during post-harvest handling and transportation (FAO).

Storage and Distribution: Once the produce reaches distribution centers, it must be stored in optimal conditions to maintain freshness. Cold storage facilities are essential for preserving the quality of perishable items. However, fluctuations in temperature, humidity, and other environmental factors can degrade the produce. Additionally, the distribution process must be efficient to ensure that the produce reaches retailers and consumers without unnecessary delays. According to the Global Cold Chain Alliance, the global cold storage market is expected to grow at a CAGR of 13.5% from 2020 to 2025 (GCCA).

Retail and Consumer Access: The final stage of the supply chain involves delivering fresh produce to retailers, where it is made available to consumers. Retailers must ensure proper handling and display of the produce to prevent damage and spoilage. The quality and availability of fresh produce at the retail level directly impact consumer satisfaction and purchasing decisions. A study by McKinsey & Company found that food waste in retail and distribution can be as high as 30% (McKinsey).

Key Supply Chain Challenges in the Fresh Produce Industry

Perishability and Shelf Life

Challenge: Fresh produce is highly perishable, with a limited shelf life that can range from a few days to a few weeks. The perishable nature of these products makes them vulnerable to spoilage during transportation and storage, leading to significant losses if not handled properly.

Solution: Implementing cold chain logistics is essential to maintaining the freshness of produce. Cold chain systems involve the use of refrigerated vehicles, temperature-controlled storage, and real-time monitoring to ensure that produce remains at optimal temperatures throughout the supply chain. Additionally, adopting modified atmosphere packaging (MAP) can help extend the shelf life of fresh produce by altering the composition of gases within the packaging to slow down the ripening process (FAO).

Transportation and Logistics

Challenge: Transportation is a critical bottleneck in the fresh produce supply chain. Delays, inadequate infrastructure, and lack of proper temperature control during transportation can lead to significant spoilage and waste. The global nature of the fresh produce trade further complicates logistics, as produce often needs to be transported over long distances, crossing international borders and multiple time zones.

Solution: Optimizing transportation routes and schedules can minimize delays and ensure timely delivery of fresh produce. Investing in refrigerated transport vehicles (reefers) and advanced tracking systems can help monitor the condition of produce in real-time, allowing for quick intervention if issues arise. Additionally, leveraging technology such as GPS and IoT devices can enhance supply chain visibility, enabling better coordination and decision-making (Gartner).

Post-Harvest Losses

Challenge: Post-harvest losses are a major issue in the fresh produce industry, with an estimated 30-40% of global produce being lost before it reaches consumers (FAO). These losses occur due to improper handling, inadequate storage, and inefficient transportation.

Solution: Implementing best practices for post-harvest handling, such as proper sorting, grading, and packaging, can reduce losses. Training farmers and workers in post-harvest management techniques is also crucial. Additionally, investing in modern storage facilities and equipment, such as cold rooms and climate-controlled warehouses, can help preserve the quality of produce during storage and distribution (World Bank).

Regulatory Compliance

Challenge: The fresh produce industry is subject to strict regulations and standards related to food safety, quality, and traceability. Compliance with these regulations can be challenging, especially for small and medium-sized producers who may lack the resources to meet all the requirements. Non-compliance can result in rejected shipments, fines, and damage to brand reputation.

Solution: Implementing a robust traceability system is essential for ensuring regulatory compliance. Traceability involves tracking produce from the farm to the consumer, documenting every step of the supply chain. This not only helps in meeting regulatory requirements but also enhances transparency and accountability. Additionally, obtaining certifications such as GlobalGAP, HACCP, and ISO can demonstrate a commitment to quality and safety, making it easier to access international markets (GlobalGAP).

Sustainability and Environmental Impact

Challenge: The fresh produce supply chain has a significant environmental footprint, particularly in terms of water usage, carbon emissions, and waste generation. Consumers and governments are increasingly demanding sustainable practices, putting pressure on producers and supply chain stakeholders to reduce their environmental impact.

Solution: Adopting sustainable farming practices, such as drip irrigation and organic farming, can reduce water usage and minimize the use of harmful chemicals. In the supply chain, using energy-efficient transportation and storage solutions can lower carbon emissions. Additionally, reducing food waste through better handling, storage, and packaging practices contributes to sustainability. Companies can also explore opportunities for recycling and repurposing organic waste, such as composting and biogas production (IFAD).

Labor Shortages and Workforce Management

Challenge: The fresh produce industry relies heavily on manual labor for tasks such as harvesting, sorting, and packaging. However, labor shortages and high turnover rates can disrupt the supply chain, leading to delays and increased costs. The seasonal nature of fresh produce farming further exacerbates this issue, as labor demand fluctuates throughout the year.

Solution: Investing in automation and mechanization can help mitigate labor shortages by reducing the reliance on manual labor. Technologies such as robotic harvesters, automated sorting systems, and AI-powered quality control can increase efficiency and reduce labor costs. Additionally, providing fair wages, benefits, and training opportunities can help attract and retain a skilled workforce (McKinsey).

Market Volatility and Demand Forecasting

Challenge: The fresh produce market is highly volatile, with prices and demand fluctuating due to factors such as weather conditions, economic shifts, and consumer preferences. Inaccurate demand forecasting can lead to overproduction, underproduction, or mismatched supply, resulting in financial losses and waste.

Solution: Advanced data analytics and machine learning algorithms can improve demand forecasting by analyzing historical data, market trends, and external factors. These technologies can provide more accurate predictions, allowing producers and suppliers to adjust their operations accordingly. Additionally, implementing flexible supply chain strategies, such as dynamic pricing and inventory management, can help mitigate the impact of market volatility (Deloitte).

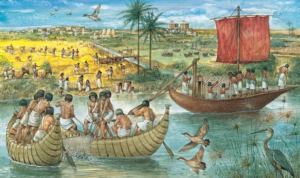

Case Study: Overcoming Supply Chain Challenges in Egypt’s Fresh Produce Industry

Egypt is a significant player in the global fresh produce market, known for exporting a wide range of fruits and vegetables, including bananas, citrus, and onions. However, the country faces unique supply chain challenges, including water scarcity, infrastructure limitations, and logistical bottlenecks.

Gezira United, a leading exporter of Egyptian fresh produce, has implemented several strategies to overcome these challenges and ensure the timely delivery of high-quality products to international markets.

Adoption of Drip Irrigation: Gezira United has pioneered the use of drip irrigation technology in banana farming, significantly reducing water usage while maintaining high crop yields. This sustainable practice not only conserves water but also improves the quality of the produce, making it more competitive in global markets.

Investment in Cold Chain Infrastructure: To address the perishability of fresh produce, Gezira United has invested in state-of-the-art cold chain infrastructure, including refrigerated transport vehicles and climate-controlled storage facilities. This ensures that their produce remains fresh and retains its quality throughout the supply chain.

Compliance with Global Standards: Gezira United is committed to meeting international quality and safety standards, including GlobalGAP and ISO certifications. By implementing a robust traceability system, they can track their produce from the farm to the consumer, ensuring transparency and compliance with regulatory requirements.

Leveraging Technology for Efficiency: Gezira United utilizes advanced technology, such as GPS tracking and IoT devices, to monitor the condition of their produce in real-time. This allows them to quickly address any issues that arise during transportation and storage, minimizing losses and ensuring that their produce reaches customers in optimal condition.

Strategic Partnerships and Market Expansion: To overcome market volatility and demand fluctuations, Gezira United has formed strategic partnerships with international retailers and distributors, expanding their market reach and ensuring consistent demand for their products. Their sub-brand, “Banana Island,” is a testament to their success in the global market, known for exporting premium quality bananas that meet the highest international standards (Gezira United).

The Role of Technology in Transforming the Fresh Produce Supply Chain

One of the most promising solutions to the challenges faced by the fresh produce industry is the integration of advanced technologies across the supply chain. These technologies not only enhance efficiency but also provide the data and insights necessary for informed decision-making.

Blockchain for Traceability

Impact: Blockchain technology has emerged as a powerful tool for enhancing traceability in the fresh produce supply chain. By providing a secure and immutable record of every transaction and movement of goods, blockchain ensures transparency and accountability from farm to table. This is particularly important for maintaining food safety standards and meeting regulatory requirements. A report by IBM found that blockchain could reduce food fraud by up to 90% (IBM).

Application: Companies can implement blockchain solutions to track the origin, processing, and distribution of fresh produce. This not only helps in identifying and addressing potential issues quickly but also builds consumer trust by providing verifiable information about the products they purchase.

IoT for Real-Time Monitoring

Impact: The Internet of Things (IoT) enables real-time monitoring of environmental conditions, such as temperature, humidity, and light, during transportation and storage. IoT devices can send alerts if conditions deviate from optimal ranges, allowing for immediate corrective actions. According to a study by Gartner, the number of connected IoT devices is expected to reach 25 billion by 2025, with significant adoption in agriculture and supply chain management (Gartner).

Application: Fresh produce companies can equip their supply chain with IoT sensors to monitor the condition of their products in real-time. This reduces the risk of spoilage and ensures that produce arrives at its destination in the best possible condition.

Artificial Intelligence for Demand Forecasting

Impact: Artificial Intelligence (AI) and machine learning algorithms are revolutionizing demand forecasting by analyzing vast amounts of data to predict market trends and consumer behavior. Accurate demand forecasting reduces the risk of overproduction and underproduction, leading to more efficient supply chain management. According to a report by McKinsey, AI-driven demand forecasting can reduce forecast errors by up to 50% (McKinsey).

Application: Fresh produce companies can implement AI-driven tools to analyze historical sales data, weather patterns, and other external factors to optimize their production and distribution strategies. This helps in aligning supply with demand, reducing waste, and maximizing profitability.

Sustainability as a Competitive Advantage

In an increasingly environmentally conscious world, sustainability is not just a regulatory requirement but also a competitive advantage. Consumers and retailers are prioritizing products that are grown, processed, and transported with minimal environmental impact.

Water Conservation Techniques

Impact: Water scarcity is a significant concern in agriculture, particularly in regions like Egypt where fresh produce farming is a major industry. Techniques such as drip irrigation, which delivers water directly to the roots of plants, can reduce water usage by up to 60% compared to traditional irrigation methods (FAO).

Application: Fresh produce companies, like Gezira United, are leading the way in adopting water-efficient farming practices. By investing in drip irrigation and other water conservation technologies, they are not only preserving a vital resource but also improving crop yields and quality.

Reduction of Carbon Footprint

Impact: The fresh produce supply chain contributes to greenhouse gas emissions, particularly through transportation and refrigeration. By adopting energy-efficient technologies and optimizing logistics, companies can significantly reduce their carbon footprint. A report by the Environmental Protection Agency (EPA) suggests that the food sector accounts for approximately 13% of total U.S. greenhouse gas emissions (EPA).

Application: Companies can explore alternative transportation methods, such as rail or sea freight, which have lower emissions than air transport. Additionally, investing in renewable energy sources for refrigeration and storage facilities can further reduce the environmental impact of the supply chain.

Sustainable Packaging Solutions

Impact: Packaging is a critical aspect of the fresh produce supply chain, but it also contributes to waste and environmental pollution. The shift towards sustainable packaging solutions, such as biodegradable or recyclable materials, is gaining momentum. According to a report by the Ellen MacArthur Foundation, transitioning to a circular economy in packaging could reduce plastic waste by 80% by 2040 (Ellen MacArthur Foundation).

Application: Fresh produce companies can adopt eco-friendly packaging materials that not only protect the produce but also reduce the environmental impact. Additionally, designing packaging that extends the shelf life of produce can help reduce food waste.

The Future of the Fresh Produce Supply Chain

As the fresh produce industry continues to evolve, the importance of a resilient and adaptable supply chain cannot be overstated. The challenges discussed in this article underscore the need for continuous innovation, collaboration, and investment in new technologies and sustainable practices.

Collaborative Supply Chain Models

Impact: Collaboration among stakeholders in the supply chain, including farmers, distributors, retailers, and technology providers, is essential for overcoming challenges and improving efficiency. Collaborative models, such as shared distribution networks and joint ventures, can reduce costs and enhance supply chain resilience.

Application: Companies can explore partnerships with logistics providers and technology firms to develop integrated supply chain solutions. These partnerships can leverage shared resources, such as transportation and storage facilities, to optimize operations and reduce costs.

Investment in Research and Development

Impact: Continuous investment in research and development (R&D) is crucial for driving innovation in the fresh produce supply chain. R&D can lead to the development of new crop varieties, advanced processing techniques, and innovative packaging solutions that enhance the quality and sustainability of fresh produce.

Application: Companies can allocate resources to R&D initiatives focused on improving agricultural practices, post-harvest handling, and supply chain logistics. Collaboration with academic institutions and research organizations can also accelerate the development and adoption of new technologies.

Consumer Engagement and Education

Impact: Engaging consumers and educating them about the importance of sustainable practices in the fresh produce supply chain can drive demand for responsibly sourced products. Informed consumers are more likely to support brands that prioritize environmental stewardship and social responsibility.

Application: Companies can launch consumer education campaigns that highlight their commitment to sustainability and quality. Providing transparency through traceability systems and certifications can also build consumer trust and loyalty.

Conclusion

The fresh produce industry faces numerous supply chain challenges that can significantly impact the quality, availability, and sustainability of products. However, by adopting advanced technologies, sustainable practices, and efficient logistics strategies, companies can overcome these challenges and thrive in a competitive market.

As consumer demand for fresh and high-quality produce continues to grow, the ability to navigate supply chain complexities will be a key determinant of success. By investing in innovation and fostering collaboration across the supply chain, the fresh produce industry can ensure a resilient and sustainable future.

References:

Explore

-

Fruit Logistica 2024 with the IPD

-

From Pharaohs to Ports: Egypt's Produce Export Journey

-

Egyptian Red Onion: Now Available with the Best Price!

-

A Guide to Egyptian fruit and Vegetable Exporters and Growers

-

Why You Should Import Egyptian Fruits and Vegetables

-

Egyptian garlic: Reasons behind importers' growing preference for it

-

Unveiling the Superiority of Egyptian Onions in the Global Export Market

-

Drip Irrigation: Nurturing Crops, Preserving Resources

-

VIDEO: 2024 Fruit Logistica Summed Up - Valuable Insights

-

Egyptian Citrus: A Global Treasure